In today's demanding industrial environments, the POWEVER A2 series servo motors (PE200 0.75KW and PE500 1.5KW) represent a breakthrough in high-speed door automation technology. Designed specifically for intensive industrial applications, these compact yet powerful servo solutions combine precision engineering with robust performance.

1.Integrated Drive Unit Design

Combines motor and drive in one compact housing

Reduces installation space by 40% compared to conventional systems

Simplified wiring with plug-and-play connectivity

2.Internal Absolute Encoder System

17-bit high-resolution encoder (131,072 pulses/revolution)

Eliminates the need for homing after power cycles

Maintains position accuracy even during power interruptions

3.Torque Auto-Adjusting System (TAS)

Dynamically adapts to load variations in real-time

Compensates for door weight changes and environmental factors

Reduces mechanical stress by up to 30%

4.LCD Display with English Interface

Intuitive parameter setting and troubleshooting

Real-time monitoring of operation status

Quick access to error history and diagnostics

5.Modbus Protocol Support

Seamless integration with industrial automation systems

Enables centralized control and monitoring

Supports RS-485 communication standard

1:Rapid Response: Achieves acceleration from 0-1,500 rpm in just 50ms

2:Precision Control: Positional accuracy of ±0.01° for smooth door operation

3:Durability: Rated for >1 million operation cycles at full load

4:Energy Efficiency: Regenerative braking recovers up to 30% of kinetic energy

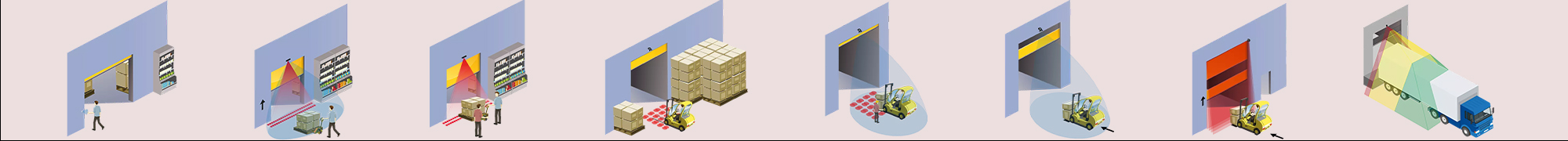

Application Scenarios

1.Logistics Warehouses

Withstands heavy industrial door panels (up to 160kg)

Installation and Maintenance Considerations

Comparative Analysis:

The POWEVER A2 series sets new standards for servo-driven PVC high-speed doors, offering unparalleled reliability for 24/7 industrial operations. Its combination of compact design, intelligent torque management, and seamless connectivity makes it the ideal solution for modern automation requirements.

The new standard set by the POWEVER A2 series servo-driven PVC high-speed doors is based on the core value of accurately responding to the key requirements of door systems in modern harsh industrial environments. These requirements are not only functional, but also the cornerstone of ensuring production continuity, efficiency and safety:

1:Ultimate reliability and uninterrupted operation: The core requirement of industry is "zero-failure" operation. The precision control and intelligent torque management of the A2 series servo system fundamentally eliminate the mechanical wear and failure risks caused by frequent start-stop and overload impact of traditional door machines. It is designed to withstand 24/7 high-intensity cycle operations, meet the stringent requirements of logistics centers, clean workshops, food processing and other scenarios for the door body to be almost "perpetually moving", minimize the risk of production line stagnation and logistics interruption caused by door failure, and ensure the absolute execution of production plans.

3:Environmental isolation and cleanliness guarantee: Industrial doors are key "environmental barriers". In industries such as food, medicine, and electronics that have extremely high requirements for temperature, humidity, and cleanliness, the A2 series high-speed doors can effectively isolate dust, mosquitoes, outdoor temperature and humidity fluctuations, and cross-contamination between areas of different cleanliness levels with their excellent sealing performance and fast opening and closing characteristics. Its stable and reliable operation ensures that this barrier is always effective, providing a basic guarantee for product quality, process stability, and energy saving (reducing the loss of cold and warm air).

4:Intrinsic safety and risk avoidance: Industrial site safety requires "nothing to lose". The intelligent torque management of the A2 series not only protects the door itself, but is also the key to active safety. It can sensitively detect obstacles (people or objects), stop or reverse when encountering obstacles, and greatly reduce the risk of pinching. The sturdy curtain material and stable running track also avoid accidents such as derailment and falling. In addition, its reliability itself also reduces the frequency of maintenance personnel's risky maintenance, avoiding safety hazards from the source.

5:Intelligent management and convenient operation and maintenance: Modern industry requires equipment to be "manageable and controllable". The "seamless connection" capability emphasized by the A2 series enables it to be easily integrated into the factory's PLC, SCADA or MES system to achieve remote monitoring, status feedback, fault warning and even automatic scheduling based on production rhythm. This not only improves management efficiency, but its modular design and long life characteristics also greatly reduce the complexity and frequency of maintenance, reduce operation and maintenance investment, and meet the requirements of lean production.

For more information, please click on the link below to learn about the product details: https://www.highspeeddoor.cn/,or contact our team directly.

For more information, please click on the link below to learn about the product details: https://www.highspeeddoor.cn/,or contact our team directly.

Company Name:Hitch (Shanghai) Automation Co.,Ltd.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:info@highspeeddoor.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800