Core Technology & Advantages

The systems of POWEVER leverage closed-loop servo control with high-resolution encoders, ensuring millimeter-accurate positioning and smooth torque management. Intelligent algorithms adapt to load variations (wind resistance, weight shifts) and environmental factors, preventing jams and reducing mechanical stress. Built-in CANopen/EtherCAT interfaces enable seamless PLC integration, while IP65-rated electronics withstand harsh industrial environments.

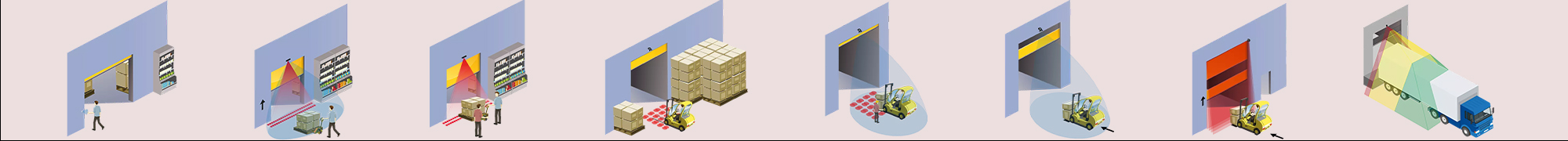

Transformative Applications

Cold Chain Logistics: C60 maintains airtight seals in freezer warehouses (-30°C), preventing energy loss.

The POWEVER Advantage

Beyond specifications, POWEVER systems offer predictive maintenance via cloud-connected diagnostics, cutting downtime by 60%. Their modular design allows retrofitting onto existing doors. With energy recovery technology feeding braking energy back to the grid, the C40/C60 reduce power consumption by up to 30% versus traditional drives.

Automotive Manufacturing: C40 enables 20-sec cycle times for paint shop doors, synchronizing with AGV routes.

Air Cargo Terminals: C60’s hurricane-force wind resistance (up to 120 km/h) ensures uninterrupted airport operations.

Robotic Warehousing: Both systems provide PLC-ready feedback for fully automated "lights-out" facilities.

Conclusion:

The POWEVER C40 and C60 Industrial Door Servo Systems redefine performance benchmarks. The C40 delivers cost-optimized precision for daily operations, while the C60 conquers extreme industrial challenges. Together, they represent the pinnacle of intelligent door automation – enhancing safety, slashing operational costs, and enabling seamless integration into Industry 4.0 ecosystems. For facilities demanding reliability at scale, servo technology of POWEVER isn’t just an upgrade; it’s a strategic imperative.

For more information, please click on the link below to learn about the product details: https://www.highspeeddoor.cn/,or contact our team directly.

Company Name:Hitch (Shanghai) Automation Co.,Ltd.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:info@highspeeddoor.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800