Powever C500 Servo Motor

The Ultimate Solution for Industrial Sectional Doors

1. Introduction

In the era of smart warehouses and automated logistics, high-performance door systems are critical for operational efficiency. The Powever C500 servo motor redefines industrial sectional door automation with its compact design, precision control, and industrial-grade reliability. This article explores its cutting-edge features, technical specifications, and real-world applications in demanding environments.

2. Core Features & Advantages

2.1 Compact & Integrated Design

Motor + Drive Unit in One: Unlike traditional systems requiring separate components, the C500 integrates 1500W motor power and drive electronics into a single housing, saving 40% installation space.

Heavy-Duty Performance: With a 1:180 reducer ratio and 500N.m output torque, it effortlessly handles 100m² sectional doors in warehouses and factories.

2.2 Precision Control for Industrial Use

Internal Absolute Encoder: Ensures ±1mm repeatability, eliminating the need for external feedback devices.

Torque Auto-Adjusting System: Dynamically adapts to wind resistance, door weight variations, and sudden load changes, preventing motor burnout.

2.3 Smart Industrial Connectivity

Modbus Protocol (RS485): Enables remote monitoring, PLC integration, and predictive maintenance for seamless automation.

3. Technical Specifications

Parameter

|

Value

|

Power

|

1500W

|

Reducer Ratio

|

1:180

|

Output Torque

|

500N.m

|

Max Door Area

|

100m²

|

Control Interface

|

Modbus RTU/ASCII

|

Operating Temp.

|

-20°C to +50°C

|

|

|

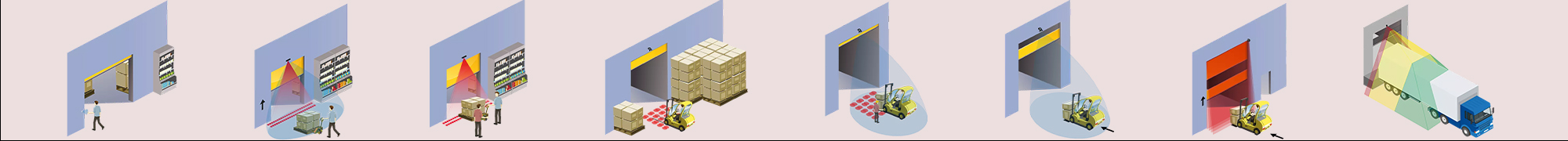

4. Industrial Applications

4.1 Warehouse & Logistics Centers

High-Cycle Operations: Optimized for frequent door openings/closing in distribution hubs.

Energy Efficiency: Reduces power consumption by 30% compared to conventional motors.

4.2 Manufacturing Plants

Dust & Corrosion Resistance: IP65-rated housing withstands harsh industrial environments.

Precise Positioning: Critical for automated material handling systems.

4.3 Cold Storage Facilities

Low-Temperature Operation: Maintains performance in freezer conditions (-20°C)

5. Why Choose Powever C500

Feature

|

C500 Advantage

|

Conventional Motors

|

Torque

|

500N.m

|

300N.m

|

Encoder Type

|

Absolute

|

Incremental

|

Communication

|

Modbus

|

None

|

The value of the Powever C500 servo motor extends beyond its impressive performance parameters, as it brings revolutionary convenience, significant energy savings, and unprecedented safety enhancements to the daily operation of industrial doors.

In terms of convenience, the integrated design of the C500 greatly simplifies the installation and commissioning process, significantly reducing labor and time costs. Its built-in intelligent control system features self-learning capabilities, automatically memorizing the optimal operating curve of the door for "one-touch setup" without the need for complicated parameter adjustments. Whether for frequently accessed logistics passages or manufacturing workshops requiring synchronization with production lines, the C500 ensures smooth door movement and precise start-stop operations, minimizing production interruptions caused by motor failures or improper adjustments, thereby enhancing overall logistics efficiency.

When it comes to energy savings, the C500 performs exceptionally well. Unlike traditional motors that consume substantial power continuously during operation and experience high current surges during start-stop cycles, the C500 adopts servo technology, consuming electricity only during movement and maintaining extremely low power consumption in standby mode. Its intelligent torque adjustment function ensures the motor operates with precisely the required power, avoiding energy waste. Overall, compared to traditional asynchronous motors, the C500 can reduce energy consumption by up to 30%, providing significant long-term savings on electricity costs for enterprises while supporting the green initiative of energy conservation and emission reduction in factories.

Safety is the cornerstone of industrial door systems, and the C500 builds multiple layers of protection. First, its precise torque control detects resistance changes in real time during door operation. If an obstacle (such as a vehicle or person) is encountered, the motor immediately stops or reverses, effectively preventing accidents and door damage. Second, the absolute encoder ensures precise door positioning, completely eliminating the risk of "drifting" or misalignment caused by cumulative errors. Even after a power outage and reboot, the system instantly recognizes the current position without requiring recalibration. Third, its strong wind resistance (thanks to the 500 N·m high torque) ensures door stability and safety under harsh weather conditions, avoiding major hazards such as doors being blown down or distorted by strong winds.

In summary, the Powever C500 servo motor, through its intelligent and integrated design, not only enhances the performance of industrial doors but also delivers qualitative improvements in operational convenience, energy savings, and safety. It is an indispensable for modern industrial door management

6. Conclusion

The Powever C500 servo motor sets a new benchmark for industrial sectional door automation. Its compact design, absolute encoder precision, and Modbus connectivity make it ideal for logistics, manufacturing, and cold storage. By combining power, intelligence, and reliability, it ensures seamless operations in the most demanding environments.

For more information about the BEA FALCON series and other products, please visit [https://www.highspeeddoor.cn/High-Speed-Door-Motor-and-Control-Panel.html].