High-Speed Door Applications in the Lime Industry

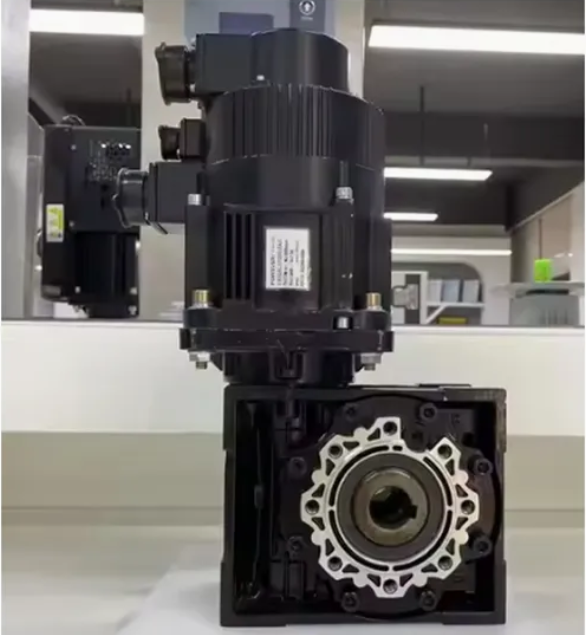

The Innovation of the POWEVER A4 PE500 Motor. Introduction: Contamination control is crucial in environments such as hospitals, pharmaceutical laboratories, and food processing plants. High-speed doors equipped with the POWEVER A4 PE500 motor are becoming an effective solution for reducing the spread of particles and microorganisms, complying with the ISO 14644-1 standard for lime areas.

Technical Features of the POWEVER A4 PE500 Motor: 1. Superior Performance, Efficiency, and Quietness: Opening/closing speed of 1.2 m/s minimizes exposure to critical areas and effectively maintains pressure differentials. Silent electromagnetic brake, ideal for sensitive operating areas.

2. Hygienic Design: Eliminate Contamination at the Source: The antimicrobial housing is made of AISI 304 stainless steel, resistant to chemical disinfectants. A silicone brush seal seals the perimeter, blocking up to 99% of particles ≥0.5 µm.

3. Industrial Intelligence for Connected Safety:System Integration Capabilities: A Modbus interface enables integration with Quality Management Systems (GxP). Intelligent safety protection: Short-circuit obstacle sensors ensure safety in high-traffic areas.

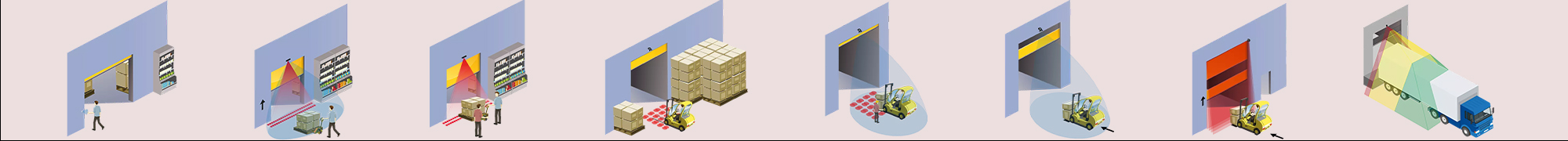

Practical Applications :

1. Hospitals and Surgical Centers: In ISO Class 5 operating rooms, high-speed doors equipped with A4 PE500 motors reduce cross-contamination by limiting air turbulence. Example: Implementation at the University Hospital of the Basque Country resulted in a 23% reduction in surgery-related infections.

2. Pharmaceutical Industry:In drug filling areas, they prevent the ingress of aerosols. Case: A German laboratory achieved EU GMP compliance by installing 12 units equipped with A4 PE500 motors.

3. Food and Biotechnology: In packaging lines, they maintain a pressure differential between clean and contaminated areas. A study in a dairy plant demonstrated a 65% reduction in bacteria counts. Comparison with Traditional Solutions: Factors: High-speed door, A4 PE500 sliding door, Opening time: 0.8 seconds, 3-5 seconds, Cleanliness: Smooth, crack-free surface, Tracks prone to dust accumulation. Conclusion: The POWER A4 PE500 motor redefines the standards for efficiency and cleanliness. Its applicability across multiple healthcare sectors, combined with sophisticated technology, makes it a strategic investment for companies focused on quality and safety. Future developments will include IoT sensors for real-time monitoring of environmental conditions. III. Comparative Advantages over Traditional Door Control Solutions

|

Factor |

High-Speed Doors A4 PE500 |

Sliding Doors |

|

Opening time |

0.8 seconds |

3-5 seconds |

|

Cleaning |

Smooth surfaces without cracks |

Rails prone to dust accumulation. |

The POWEVER A4 PE500 motor redefines the efficiency and cleanliness standards for high-speed doors in clean environments through its superior performance, proprietary hygienic design, and advanced industrial intelligence. It transcends simple aisle isolation and becomes a strategic investment for ensuring quality and safety in industries such as healthcare, pharmaceuticals, and food biotechnology.

Company Name:Hitch (Shanghai) Automation Co.,Ltd.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:info@highspeeddoor.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800