1.Vertical Integration: Top-tier manufacturers maintain complete supply chain control, from precision CNC-machined rotors to IP65-certified enclosures, creating cost advantages that surpass Western counterparts.

2.Smart Connectivity: With 78% of new models now IoT-enabled, POWEVER's cloud-based predictive maintenance systems have become the global standard for pharmaceutical cleanroom applications.

As the sector benchmark, POWEVER embodies China's manufacturing prowess:

1.Commitment: Allocating 15% of annual revenue to research, its 200-member engineering team generates 20+ patented motor designs each year.

2.Quality Excellence: Rigorous 72-hour endurance testing ensures each Roller Shutter Door Motor achieves 150,000-cycle MTBF - triple the industry norm.

3. Market Evolution & Competitive Landscape

Key industry transformations include:

1.Advanced Materials: Carbon fiber-reinforced PVC door systems now offer 60% extended service life while reducing motor workload.

2.Regional Specialization: Zhejiang's cost-optimized motors (<$500) complement Guangdong's premium 10,000RPM solutions for aerospace applications.

4. Strategic Challenges & Growth Prospects

While maintaining dominance, the sector faces critical considerations:

1.Market Consolidation: With 300+ competitors in the $1.2B domestic market, industry rationalization appears inevitable.

2.IP Protection: Continuous innovation is required to combat servo algorithm replication by competitors.

3.Global Strategy: To overcome EU tariffs (up to 27%), POWEVER has established local production through strategic Polish partnerships.

Industry analysts forecast 9.8% compound annual growth through 2030, fueled by smart warehouse expansion. With POWEVER leading in AI-optimized motor calibration and Wuhan's emerging "Motor Valley" cluster, China is positioned to sustain its 65% share of global production capacity.

In modern logistics centers, clean rooms, and busy garages, a silent flash of lightning constantly dictates the pulse of efficiency—high-speed doors suddenly rise and fall, turning spatial barriers into passages that open and close in the blink of an eye. The unsung hero behind this extraordinary speed and precise control is the precision-engineered high-speed door motor. It is not merely a physical power source but also the invisible cornerstone of seamless operations in the intelligent era.

The manufacturing philosophy of high-speed door motors is deeply rooted in the modern principle that "time is a resource." The delay in the opening and closing of traditional doors implies unnecessary energy loss, instability in temperature control, and potential safety risks. In contrast, high-performance motors, equipped with precise servo control systems and robust torque output, propel door operating speeds to an astonishing several meters per second, significantly reducing passage opening and closing time. This fleeting gap safeguards the constant low temperature in cold storage warehouses, the particle count in clean rooms, and the immeasurable efficiency of goods flow on sorting lines every second. Each near-instantaneous response deeply enhances operational cost efficiency and quality control.

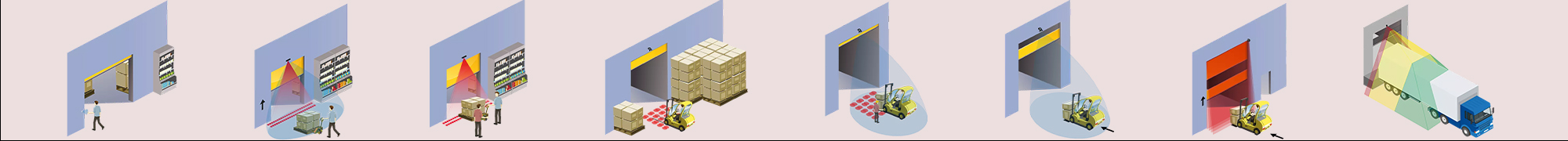

Cutting-edge manufacturing processes endow these motors with far more than just explosive speed. Integrated intelligent control units transform them into "smart nodes" capable of sensing their environment. Through programming, they can flexibly adapt to various operating modes: a gentle and quiet night mode, a full-throttle peak mode, or a collision-prevention safety mode that immediately reverses upon encountering slight resistance. Seamless collaboration with radar and induction loop sensors enables fully automatic, touch-free passage—"the door opens as vehicles approach and closes after they pass"—reducing human intervention to zero. Behind this smooth experience lies the liberation of manpower and absolutely reliable operational logic.

Durability is the gold standard for industrial products. High-speed door motors operate in harsh environments characterized by high frequency and heavy loads. The strength of their manufacturing materials, the precision of their gears, and the heat dissipation and protection ratings (e.g., IP ratings) of the motors are all refined through rigorous processes.

For more information, please click on the link below to learn about the product details: https://www.highspeeddoor.cn/,or contact our team directly.

Company Name:Hitch (Shanghai) Automation Co.,Ltd.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:info@highspeeddoor.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800