Introduction

Self-repair high-speed doors have become increasingly important in cleanroom environments due to their unique combination of speed, safety, and maintenance efficiency. These specialized doors are particularly valuable in industries requiring strict contamination control, such as pharmaceutical manufacturing, semiconductor production, and medical facilities.

Technical Features

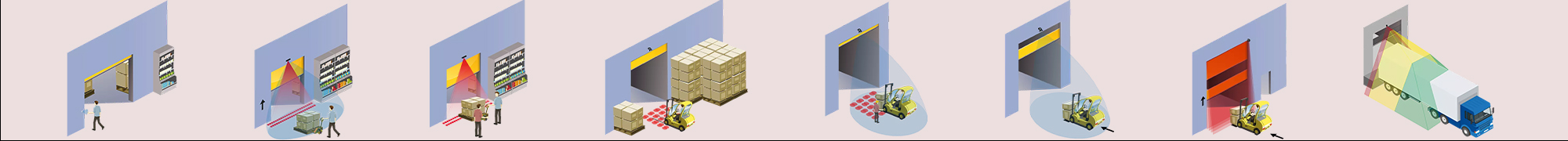

Construction System: The vertical-winding design allows for rapid operation while maintaining structural integrity. The lightweight yet robust construction minimizes potential impact force during accidental collisions.

Self-Repair Mechanism: Incorporates an automatic repair system for the shutter that activates after collisions, significantly reducing downtime in critical cleanroom operations.

Safety Features: Eliminates the need for traditional safety ribs through intelligent design that reduces kinetic energy during closure, making them ideal for high-traffic cleanroom areas.

Cleanroom Applications

Pharmaceutical Manufacturing:

Maintains ISO-classified zones by preventing airborne contamination during material transfer

The self-repair function ensures continuous operation in sterile filling areas

Semiconductor Fabrication:

Provides rapid access while controlling particulate contamination

Automatic repair minimizes production interruptions in cleanrooms requiring constant positive pressure

Hospital Operating Theatres:

Meets bacteria-controlled environment requirements

The door's hygiene features complement surgical suite cleanliness protocols

Food Processing Cleanrooms:

Withstands frequent washdown procedures

The repair system maintains functionality despite harsh cleaning chemicals

Advantages Over Conventional Doors

Operational Efficiency: Achieves opening/closing speeds up to 2-3 times faster than standard cleanroom doors, reducing air exchange losses.

Contamination Control: The smooth operation and automatic repair minimize particulate generation that could compromise cleanroom standards.

Cost Effectiveness: Reduced maintenance requirements and extended service life provide long-term savings in critical environments.

Regulatory Compliance: Meets stringent cleanroom construction standards including GB 50591-2010 for Cleanroom Construction and Acceptance Code.

Implementation Considerations

Installation Requirements: Must be integrated with cleanroom HVAC systems to maintain pressure differentials.

Validation Protocols: Requires performance verification according to cleanroom classification standards.

Material Compatibility: Surface materials must meet cleanroom cleanliness and ESD requirements.

Future Developments

Emerging technologies are combining self-repair mechanisms with advanced contamination control features such as:

Integrated air curtains for enhanced particle barrier

Smart sensors for predictive maintenance

Antimicrobial surface treatments.

Conclusion

Self-repair high-speed doors represent a significant advancement in cleanroom door technology, offering unparalleled operational reliability while meeting the stringent contamination control requirements of modern cleanroom facilities. Their unique combination of speed, safety, and self-maintenance capabilities makes them particularly valuable in mission-critical environments where operational continuity and contamination control are paramount.

For details on these solutions, visit[https://www.highspeeddoor.cn/High-Speed-Door.html]or contact our team directly.

Company Name:Hitch (Shanghai) Automation Co.,Ltd.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:info@highspeeddoor.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800