A critical component of any cold room is the door. Cold room doors are designed to maintain a controlled environment, preserving the desired temperature and preventing contamination from external factors. These doors are specifically engineered to provide an efficient barrier against thermal transfer while ensuring easy access and smooth operations.

There are several different types of cold room doors available, each with its distinct features, advantages, and applications. Let's explore these options to better understand the variety and suitability of cold room doors for different industries.

1. Hinged Doors:

Hinged doors are the most common type of cold room doors. They are typically made of stainless steel and consist of one or two panels that swing open. Hinged doors are highly durable and have excellent insulating properties, making them a cost-effective choice for most cold storage applications. These doors can also be equipped with accessories such as windows, heating devices, and locks for added functionality and security.

2. Sliding Doors:

Sliding cold room doors are a popular choice for areas with limited space or high traffic. As the name suggests, these doors slide along a track to open and close. They are often made of insulated materials like foamed polyurethane, which ensures sufficient thermal insulation. Sliding doors are easy to operate and require minimal clearance, making them suitable for tight spaces like walk-in freezers or small cold rooms.

3. Bi-Parting Doors:

Bi-parting doors consist of two panels that simultaneously move aside to open. These doors are commonly used in larger cold room applications, such as industrial warehouses or distribution centers, where large and frequent access is required. Bi-parting doors offer high-speed opening and closing, ensuring quick access while minimizing temperature fluctuations. Additionally, they can be equipped with features like air curtains or infrared sensors to help maintain temperature control.

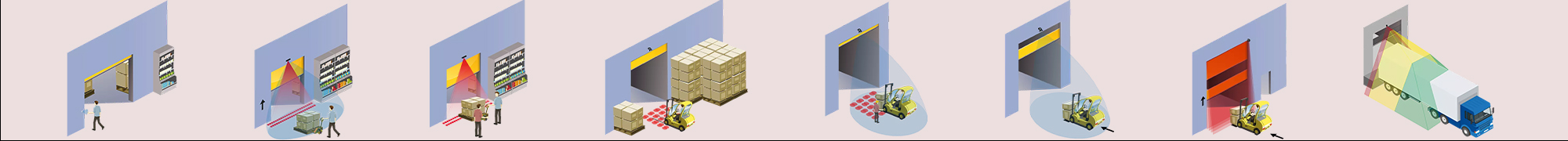

4. Rapid Roll Doors:

Rapid roll doors are designed for high-frequency access and temperature-controlled environments. These doors are made of special materials, such as PVC or fabric, with excellent insulation properties. Rapid roll doors operate at high speed, minimizing the time taken to open and close, reducing heat ingress, and preventing energy loss. They are commonly used in food processing facilities, cleanrooms, or logistics operations.

5. Freezer Doors:

Freezer doors are specifically designed to withstand extreme low-temperature environments. These doors are typically made of double-insulated panels with air barriers to prevent frost buildup. Freezer doors offer excellent thermal insulation, preventing heat transfer and maintaining the desired temperature inside. They are commonly used in commercial freezers, blast freezers, or any cold storage area where temperatures can reach sub-zero levels.

In conclusion, cold rooms require specialized doors to maintain temperature control, minimize energy consumption, and ensure optimal storage conditions. The selection of the right type of cold room door depends on various factors, including available space, traffic requirements, insulation needs, and temperature variations. Consulting professionals or cold room door manufacturers can help make an informed decision and ensure the optimal functioning of cold storage facilities.

Company Name:Shanghai Honwei Automation Co., Ltd. HITCH (SHANGHAI) IMPORT& EXPORT CO., LTD.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:sales.sh@powever.com.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800